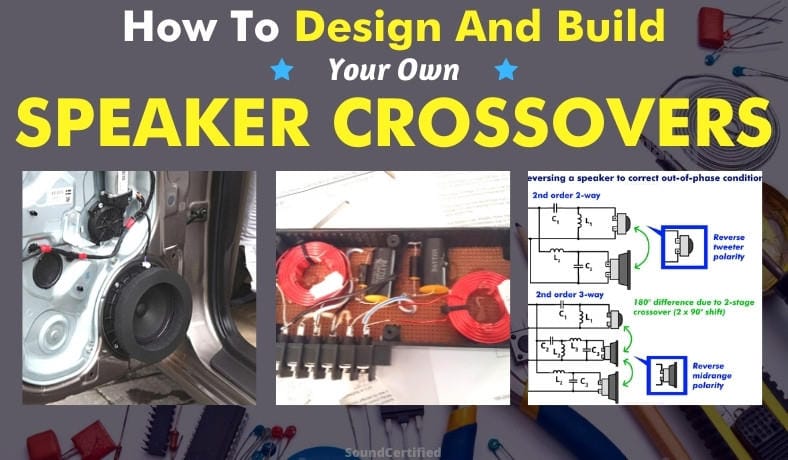

Welcome! In this big how-to guide, I’ll show you how you can design and build your own speaker crossover for home or car audio.

I’ve built many of my own – from basic ones to more advanced designs so I’d love to share what I’ve learned along the way. I’m going to cover quite a bit so let’s dig in!

Contents

- What this how-to guide covers

- How does a passive crossover work? (A brief guide for beginners)

- Choosing your crossover design type and related details

- Designing the crossover circuit and finding part values

- Getting your parts together

- DIAGRAM – How to build your speaker crossover

- Example of a finished DIY speaker crossover

What this how-to guide covers

There are so many different types and variations of passive crossover design types that it’s not practical for me to cover all of them. To keep things manageable and help the highest number of people (just like you!), I’ll cover what you need to know for building one of several options that will work for 95%+ of speaker system needs.

How this article will help you

My article will provide the know-how, diagrams, info, and steps to build a do-it-yourself (DIY) speaker crossover for getting the sound you want based on my own real-world experience doing so. It’s entirely possible to build something you’ll enjoy using and be proud of without huge headaches or going broke!

In this how-to guide I’ll cover:

- 1-way (tweeter high pass or woofer low pass), 2-way, and 3 way crossovers.

- Good first order and second order crossover design types to use.

- How to determine the cutoff frequency (crossover frequency) numbers you’ll need.

- Schematic diagrams to help you build yours which you can download or print if you like.

- What you need to know about speaker impedance (speaker Ohms) and why it matters.

- Choosing the right parts to buy and a practical approach to part values.

- What to do if you can’t find the right part values.

- Wiring up your crossover network and assembling everything (without having to build a custom circuit board).

- Additional things to do for that extra touch and even better performance.

(Feel free to skip some sections if you’re not new to some of the ideas here.)

How does a passive crossover work? (A brief guide for beginners)

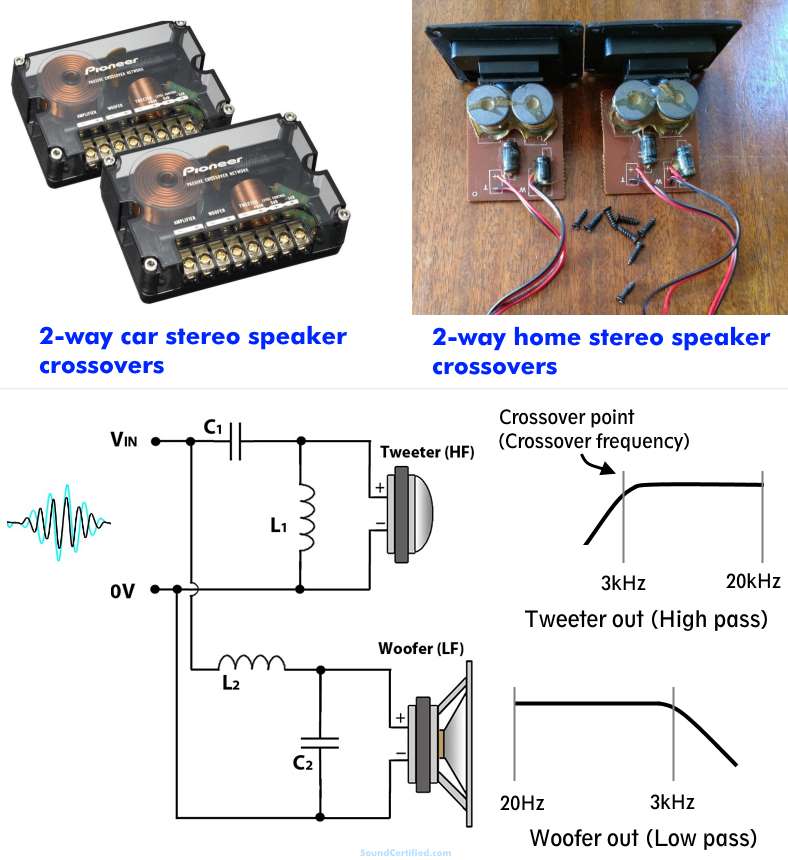

A passive crossover filter differs from an active crossover (used in electronic audio designs, amplifiers, and preamplifiers, etc.) in that it uses non-powered passive components to filter out a frequency range before it can reach a speaker. In practical terms, they effectively “block” unwanted sound frequencies from reaching a speaker driver by greatly reducing, or attenuating, the input signal from a stereo or amplifier.

This is possible due to a property of capacitors and inductors called reactance. Reactance, in short, describes the physics properties that create opposition to the flow of electrical current which also changes with the audio signal frequency.

In other words, this creates an impedance, or opposition, to the speaker voltage and therefore can pass or reduce audio power to a speaker terminals.

The role of capacitors and inductors in crossover network design

- A capacitor increases its opposition to the flow of current at frequencies below the crossover point. This means it acts as a high pass filter when connected in series with a speaker load (Ohms load).

- An inductor increases its opposition to the flow of electricity more at higher frequencies above the crossover point. This means it acts as a low pass filter when connected in series with a speaker.

The real-world uses for these are extremely important in home audio or car audio speaker systems:

- We can use the right value capacitor (rated in units called Farads) to prevent low frequency sound from reaching a tweeter which would cause distortion or even damage!

- We can use an inductor of the right value (rated in units called Henries) to prevent high frequency musical signals from reaching a woofer which would sound very poor or harsh.

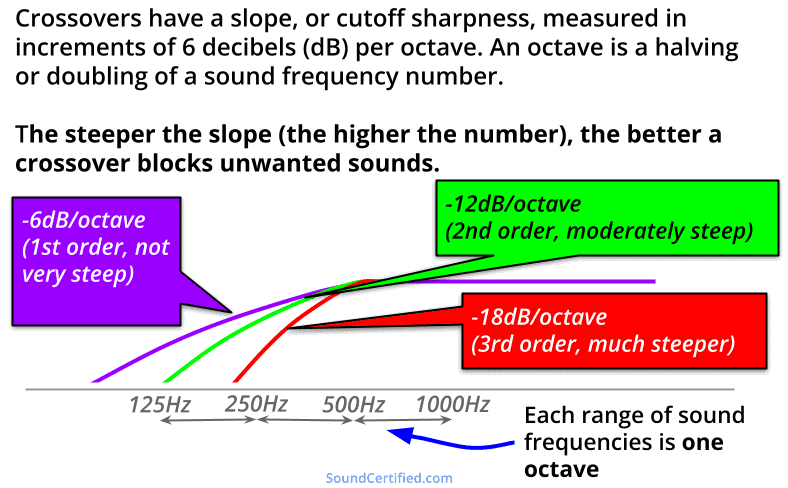

Capacitors and inductors can be used alone (single stage crossover, also called 1st order) or combined to make an even more effective filter with different characteristics. 1st order crossovers have a crossover slope, or filtering steepness/effectiveness, that rolls off at a rate of 6 dB per octave.

Second order crossovers, which have two capacitor or inductor sections, roll off their output at 12dB per octave. 2nd order designs are one of the most commonly used for passive crossovers as they’re a good compromise between complexity, cost, slope steepness, and sound quality.

A negative sign in front indicates a reduction where a positive sign or none in front indicates a gain.

Ex.: A crossover with a slope of -6dB/octave will have an output that’s reduced by 6 dB for each octave (a halving or doubling of frequency: 400Hz, 800Hz, 1,600 Hz, etc.) past the cutoff frequency.

What is a speaker crossover point?

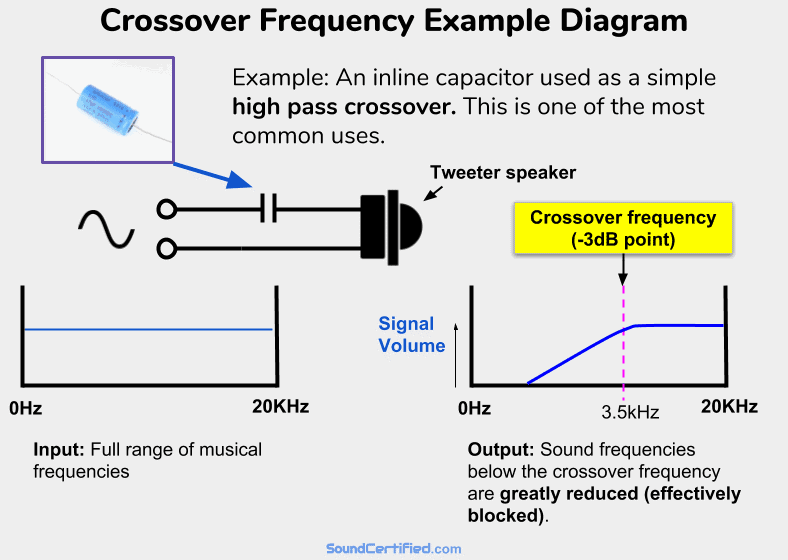

A speaker crossover point is usually called a crossover frequency and it’s sometimes written as “Fc” to represent the “cutoff frequency.” A speaker crossover point is the cutoff frequency beyond which audio frequencies are greatly reduced from reaching speakers, effectively blocking them.

In technical terms, it’s based on the point at which the output of a crossover has a loss of 3dB. In electrical power terms, the -3dB point is the frequency at which the power to the speaker is reduced by 1/2.

As we get further past the crossover frequency (the -3dB point) the output will decrease more and until it’s essentially zero. For example, for a -6dB/octave tweeter crossover with a cutoff at 1kHz:

- The tweeter will have a -3dB output at 1kHz.

- At one octave away (500Hz), the output will be -6dB.

- At frequencies even further away the output will be nearly 0 decibels.

Choosing a crossover type and slope

Here are some recommendations for the best crossover slope and crossover order types to use based on your speaker system. Note that these are generally the most popular and work for most cases.

- For a simple tweeter crossover (high pass, for treble or “highs”) or woofer or midrange speaker crossover (to pass a low frequency signal) a 1st order, 6dB/octave type is usually fine. Second order, 12dB/octave designs are optional as well if you want to filter out unwanted frequencies even more sharply.

- For 2-way speaker systems a 2nd order Linkwitz-Riley is often the best compromise between sound quality and performance. Although 1st order is simple and easier to build it’s not ideal unless you have a specific reason to do so. Another benefit is that they provide an in-phase speaker output when used correctly (I’ll cover this later).

- For 3-way designs a second order type is fine and also avoids issues with phase problems and other complexities that can come up.

Linkwitz-Riley vs Butterworth and other 2nd order crossover types

Linkwitz-Riley designs are hands-down one of the most commonly used for a number of reasons – the main one being its flat response where the woofer and tweeter crossover point outputs overlap. Other designs like Butterworth, Chebychev, and Bessel don’t offer the same frequency response although they do offer various amounts of gain which can be useful for specific design goals.

The Linkwitz-Riley (L-R) crossover is an excellent choice for building a standard speaker design with its -12dB per octave slope and good (flat) output.

The flat magnitude response, low sensitivity to offset, and in-band driver resonances have made the L-R a popular choice among manufacturers.Vance Dickason, The Speaker Design Cookbook (7th ed.)

Although it’s a separate topic, the L-R crossover isn’t sensitive to speaker driver resonance which is another benefit. If you’re interested in learning more I encourage you to get your hands on a copy of Vance Dickason’s The Loudspeaker Design Cookbook.

How to find your crossover frequency values

The good news is that there are a few ways to tell what crossover frequency you should pick to design & build your own:

- Manufacturer recommendations.

- The speaker’s frequency response if that specification is provided. (It’s not always available, unfortunately!)

- General rules of thumb based on the type and size of the speakers you have (tweeters vs woofers, small cone vs big cone speakers, etc.).

You’ll probably end up using 2 or more of the things above to get the best results.

1. Manufacturer recommendations

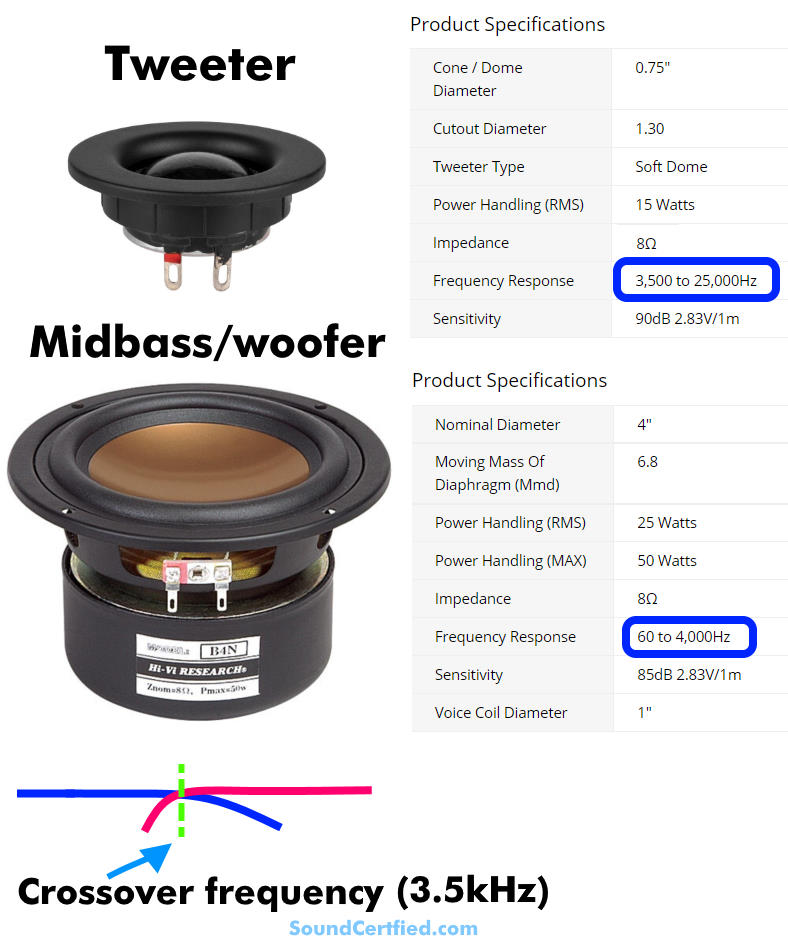

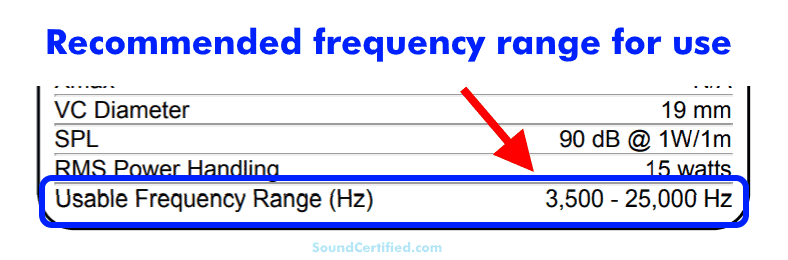

If you’re fortunate your speaker company may have provided a good frequency range for use. For the example pictured above you’d pick a crossover frequency of at least 3.5kHz which happens to be a very common one.

2. Driver frequency response chart or specifications

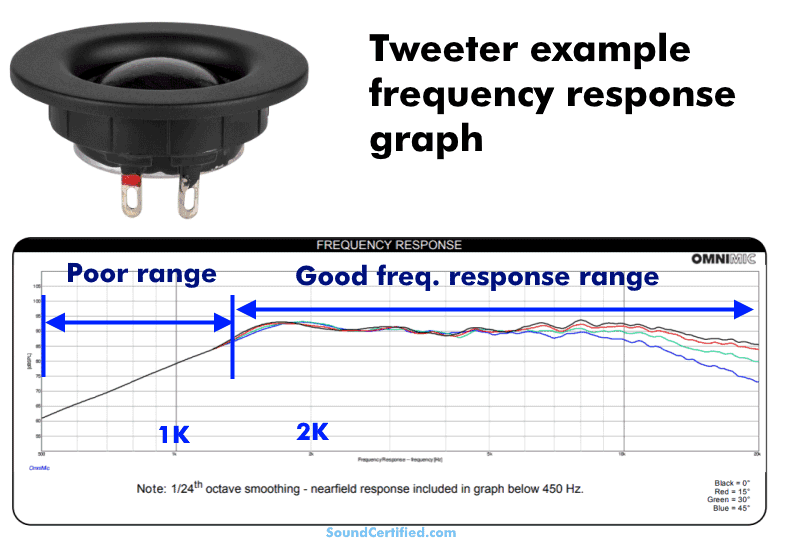

If you’re lucky enough to have a frequency response graph with the speakers you’d like to use you can see the areas where they have a poor output and use this as a guide. These are the areas you’ll want to avoid.

To do so, pick a crossover frequency away from this range. When using 2 or 3-way setups this should ideally be the point at which the other driver or drivers can produce sound as well. The idea is to find a “middle point” that both can produce sound up to that point without a gap, or significantly weaker, range of output.

From the example above, we can see that the tweeter shown has a good output until somewhere below 2 kiloHertz (2kHz). Knowing that we’ll want to choose a crossover frequency that’s at least 2kHz or higher.

3. Speaker size and type

To pick the cutoff needed based on your speaker driver size and type the following rules of thumb are helpful:

- Tweeters use a small driver that can’t handle bass or midrange in many cases. Most can produce sound from about 3kHz and above, so a 3kHz or 3.5kHz high-pass cutoff frequency is usually a great choice.

- A midrange speaker used in a 2-way design is usually also good to about 3kHz-3.5kHz. [For a midrange driver in a 3-way design see my notes further below.]

- Woofers that produce some midbass or midrange frequencies often need a low pass around 120 to 250Hz.

- Subwoofers do poorly with anything other than a very limited low frequency range so 80-100Hz is often best. 120Hz is applicable in some cases as well.

3-way crossover frequency notes

Although it might not seem like it, 3-way crossovers aren’t just a simple extension of a 2-way design. The idea, in this case, is to use an all pass crossover (APC) design with a large frequency range between the high pass frequency and the low pass frequency.

That’s because undesirable interactions can happen if they’re too close together. You can use my table below or this general rule based on the ratio of the high pass cutoff (Fh) and low pass cutoff (Fl):

Some great 3-way crossover frequencies to use are:

- 3kHz/375Hz

- 5kHz/625Hz

- 6kHz/750Hz

To use the 1:8 ratio above, pick the upper frequency and divide by 8 to get the 2nd. Likewise, you can pick a lower frequency and multiply by 8 to get a good upper cutoff frequency.

Note that 3-way designs have a midrange output with a higher or lower dB level. In this case, the 3-way design has a 2.45 dB gain compared to the tweeter and woofer outputs which is pretty small.

Crosspoints closer together than the three-octave ideal will suffer from complicated undesirable interference patterns.Vance Dickason

Designing the crossover circuit and finding part values

Once you’ve got the following:

- The crossover type you need.

- The crossover frequencies.

- Your speakers and their impedance (speaker Ohms rating).

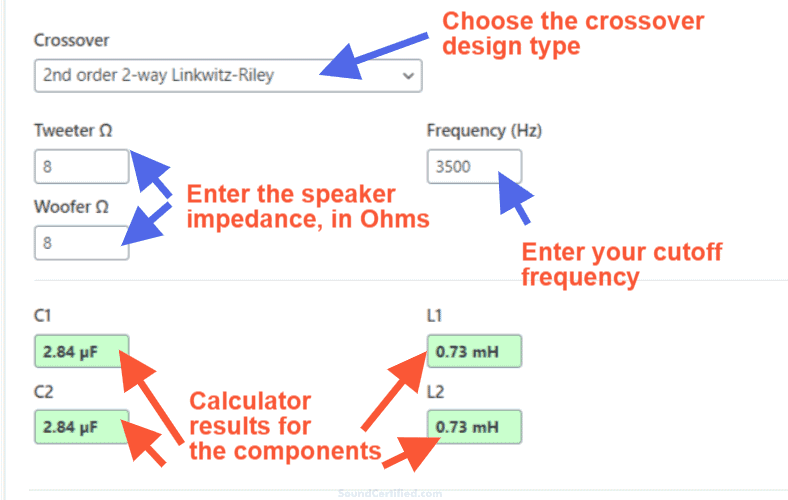

…you can get down to work! The good news is it won’t be very hard – you don’t have to do the math yourself unless you prefer to. You can use my speaker crossover calculator to give you the part values you need.

Using a crossover calculator

It’s fairly self-explanatory but not to worry as I’ve provided instructions on the calculator page. Enter your values and selections for:

- The crossover type (a diagram will be displayed to clarify it).

- The speaker impedances used.

- The crossover frequency/frequencies as needed.

Write down or save the values, either on the schematics below or somewhere else you can find them.

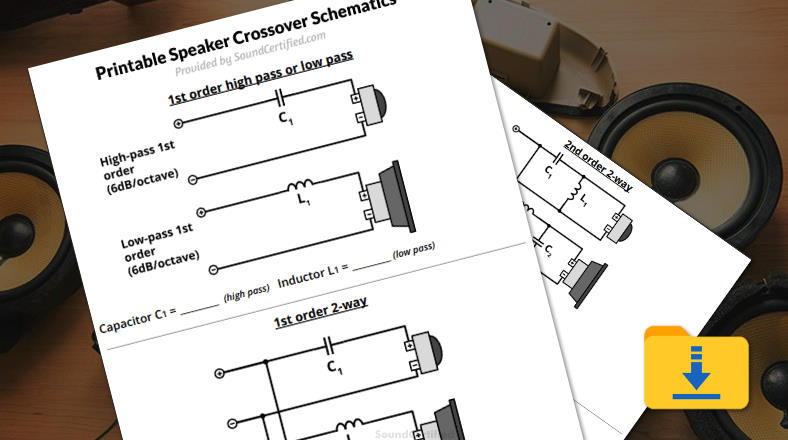

DIAGRAMS – crossover network schematics to print and use

Click here to view or print the crossover schematics provided for building your DIY crossover. Space is provided on the printout to write down your calculated part values if you like.

Getting your parts together

Shopping for crossover components

You’ll need the following types of crossover components at a minimum:

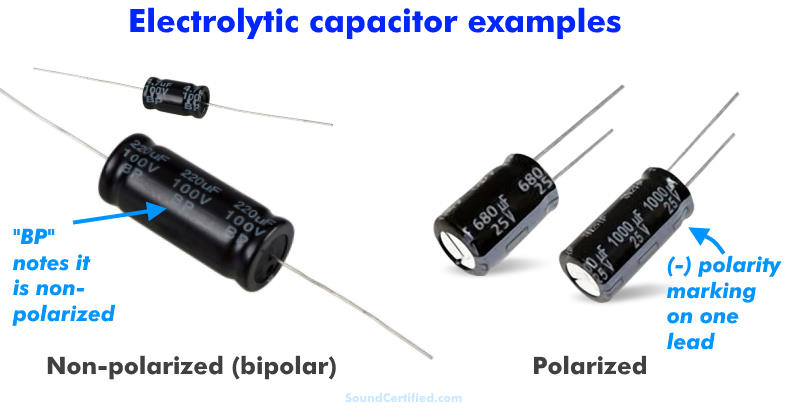

- Electrolytic non-polarized (bipolar) capacitors with a sufficient voltage rating. This is generally about 48V or higher rated.

- Air core inductors, although ferrite bobbin (ferrite core) types are fine too but not required.

Capacitors are rated in units called Farad and usually sold in “microFarad”, also sometimes written with the greek symbol Mu (µF, 1/1,000,000 of a Farad) or with a small “u” (uF). Inductors are measured in Henries and usually sold in milliHenries (1/1,000 of a Henry) written as “mH”.

Bipolar versus polarized capacitors

Polarized capacitors are the most common type but won’t work for audio use – you MUST use non-polarized types. That’s because 1) they can’t handle an alternating current (AC) voltage that reverses and 2) they can distort the sound and even fail. Non-polarized capacitors allow an electrical musical signal to pass fine.

Bipolar (“BP”, non-polarized) capacitors are usually marked as such while polarized types have one side with a stripe marking the negative connection.

Capacitor voltage ratings

Capacitors can’t handle a voltage applied that’s over there maximum rating. 48V or higher is a good rule of thumb although you can calculate the minimum value yourself using Ohm’s law if you know the amp’s RMS power rating like so:

For example an amp with 50W per channel to a 8 ohm speaker will have an output voltage of about square root(50 x 8) = 20V. A higher voltage rating would be fine but we don’t want to go below 20V. We’d use the next largest rated part we find or higher.

Part value tolerances (why not to look for “perfect” values)

Electrolytic capacitors and air core inductors have a tolerance of about plus or minus 20% of their labeled value (+/-20%). More expensive parts may have 10% or lower tolerance which is nice but not really necessary.

I say this to help get the point across that:

- No capacitor or inductor will have a perfect value – they vary slightly from their rated value.

- You don’t need an exact value, but rather the goal is to get it pretty close to the value you need.

- Inductors, capacitors, and resistors are sold in standardized values and you’ll almost never find the EXACT value. In many cases it’s not stocked by a supplier and not worth the time trying to search and search for it.

For example, a capacitor labeled as 4.7 uF (4.7 microFarad) may have an actual of around 3.76 to 5.64 uF when measured with test equipment. (It’ll probably be around 4 to 5uF but you see what I mean). The same is true for inductors too.

In that case, you’d buy a 4.7uF one if it’s reasonably easy to get but if not, the good news is there’s another way.

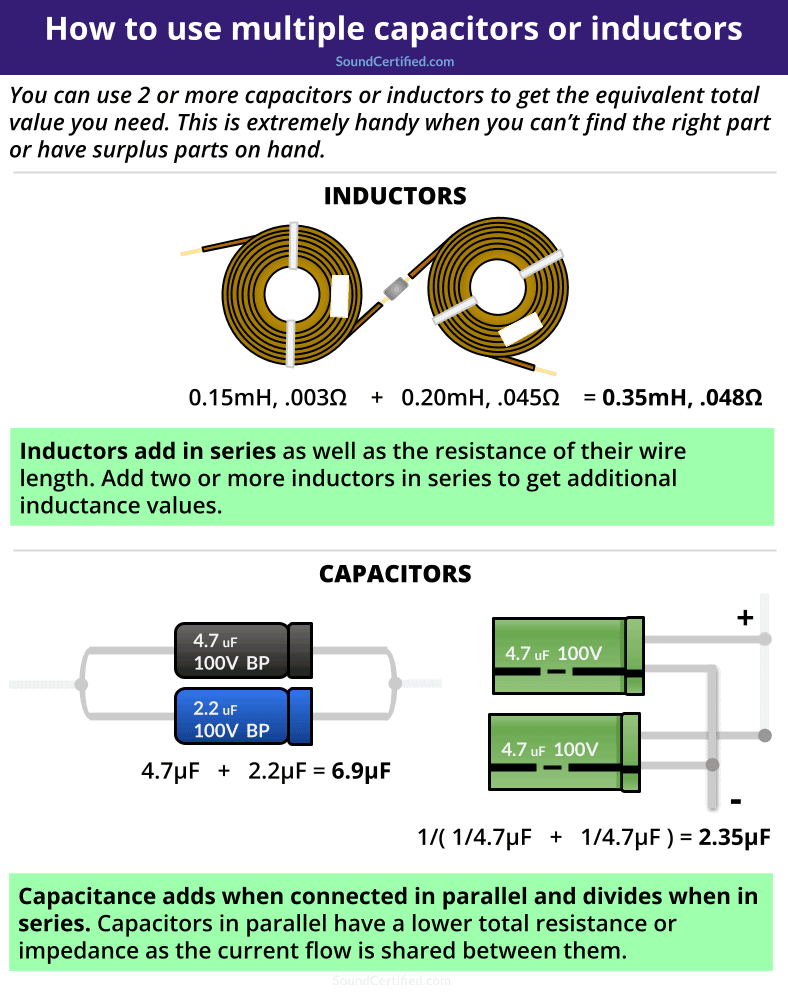

TIP: How to get the part values you need if you can’t find them

There’s a simple way to handle not finding the exact part values you need. The trick is to use multiple crossover components in such a way that they add up close to what you’re after.

- Inductance adds when they’re connected in series and divides when wire in parallel.

- Capacitance adds (sums) when they’re wired in parallel. The total capacitance divides when connected in series.

This means you can use spare parts or buy other parts of different values that are available to accomplish the same thing!

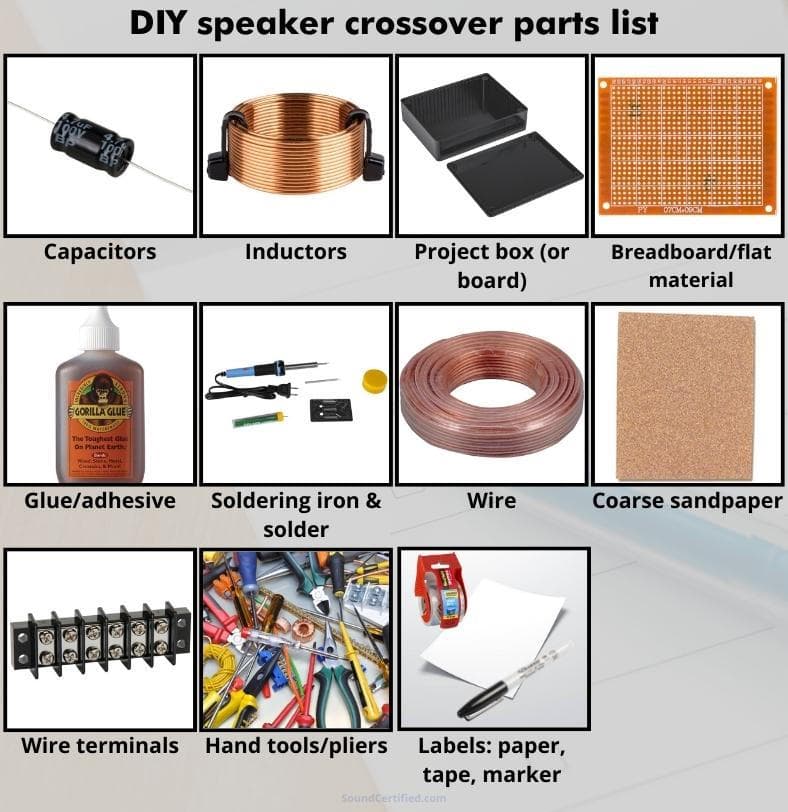

Miscellaneous parts you’ll need

I can’t recommend enough being prepared. Here’s a general list of what you’ll need to build and encase your passive speaker crossovers:

- Project enclosure (if not being mounted directly inside a speaker cabinet), ideally made of ABS plastic.

- [Optional] Breadboard or other flat material for a mounting surface.

- Speaker wire or miscellaneous wire for connecting the components to each other and wire terminals.

- Sandpaper or metal file to remove insulating enamel from inductor wire ends.

- Wire terminals: I use a dual row inline wire terminal strip as they’re relatively easy to get, not expensive, and can be mounted with screws.

- Adhesive to mount your parts: General adhesive, silicone-based adhesive, or a hot glue stick and a hot glue gun (although not recommended for hot areas).

- [Optional] Labels: Clear Scotch tape or shipping tape and white paper + permanent marker or black & white printer.

- Typical hand tools: cutting pliers or needle nose pliers, Philips screwdriver, and others as needed.

I recommend always checking how much room you’ll need based on the size of your capacitors and inductors.

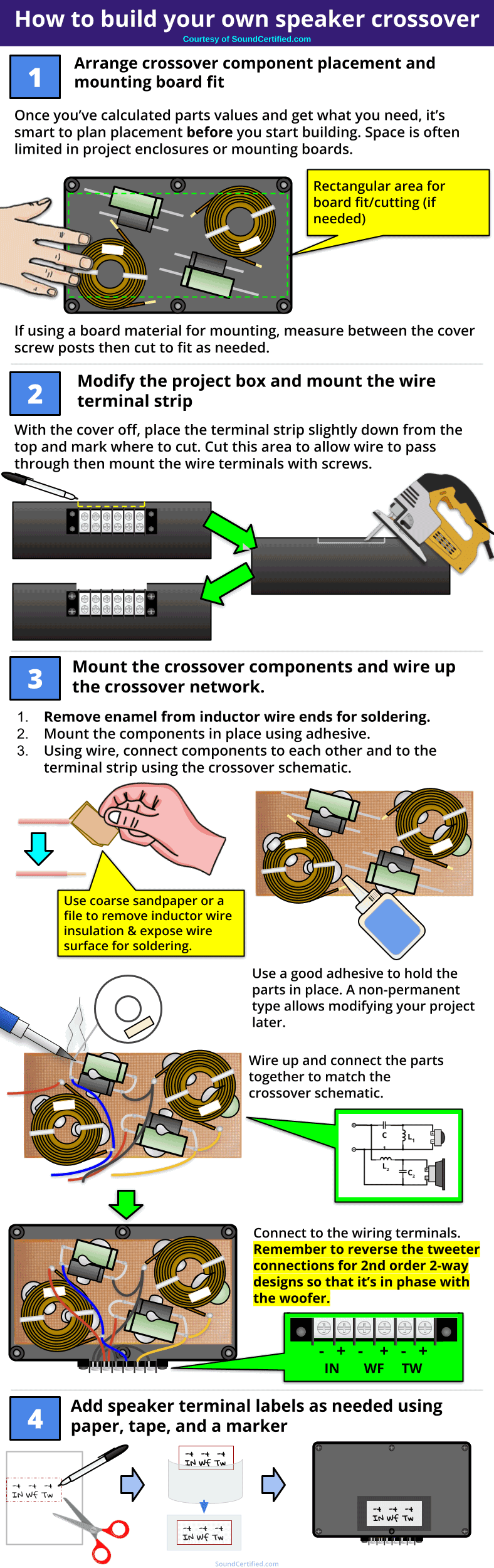

DIAGRAM – How to build your speaker crossover

Prepare the crossover circuit & components for assembly

Once you’ve got your parts and the schematic it’s time to jump right in! To build your crossovers, I recommend doing the following:

- Place the capacitors and inductors in the project box in order to figure out the best placement before you start building. Sometimes space is tight and you don’t want problems when you’re already in the middle of building the crossover network circuitry.

- If you’re using a mounting board or perfboard, etc., measure between the cover screw columns. This is important because many plastic project enclosures have screw bases that take up space on the inside. Cut your board as needed to fit this area.

- Although it can be possible to find a single-row wire terminal strip they’re hard to get. I recommend using a dual row strip as they’re affordable and much easier to find.

- With the top on the box, place the terminal strip slightly below the top to leave enough room for wiring to exit below the cover when it’s on. Using a permanent marker or knife, mark the area above it and cut that section of plastic out.

Mounting & connecting your components

- I recommend using a non-permanent adhesive like hot glue and a hot glue gun, silicone sealant, contact adhesive, Gorilla Glue, etc. to mount the parts. This way you can remove them later if you need to modify the design or reuse parts.

- For warmer temperatures hot glue really isn’t so great. Hot glue can become detached from the mounting surface in warm temperatures and doesn’t stick well to smooth surfaces like ABS plastic, either. For that reason I don’t recommend it in most cases.

- Inductors use magnet type wire which has an enamel insulator you’ll need to remove with coarse sandpaper, a file, or Dremel tool. In order to solder the wire ends, you’ll need to expose the wire surface and provide a good clean contact area.

- You can use spare speaker wire or miscellaneous stranded hookup wire to connect the components together.

You can also use crimp connectors instead of a soldering iron and solder, although I personally recommend soldering for the best connection possible.

Going by the crossover schematic, connect each section to the next and double-check your work.

Proper placement of inductors

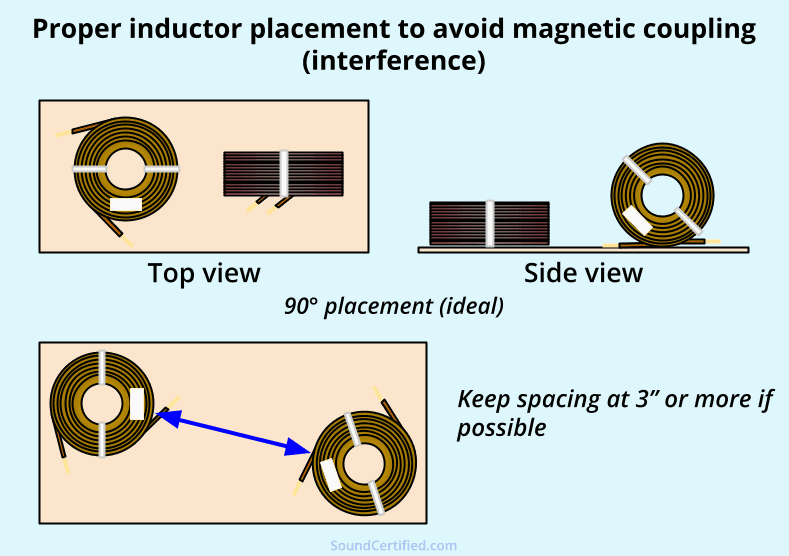

Inductors, as you may already know, work by increasing the magnetic field strength using loops of wire. Because of this it’s possible for one to cause magnetic coupling (interference) which can induce a signal or distortion in another.

To avoid this, if at all possible mount them at a 90° difference as shown in the diagram above or a minimum of about 3 inches. I begin by placing them at opposite corners of the box when building mine.

Putting it in a project enclosure

Once you’ve got the crossover circuit built, place the whole assembly in the box and use a bit of adhesive to hold it inside if you like (optional). Connect the amp side wiring, negative side wiring, and speaker output wires to the terminal strip on the top row.

This will leave the bottom row free for speaker connections.

Speaker terminals and tweeter polarity

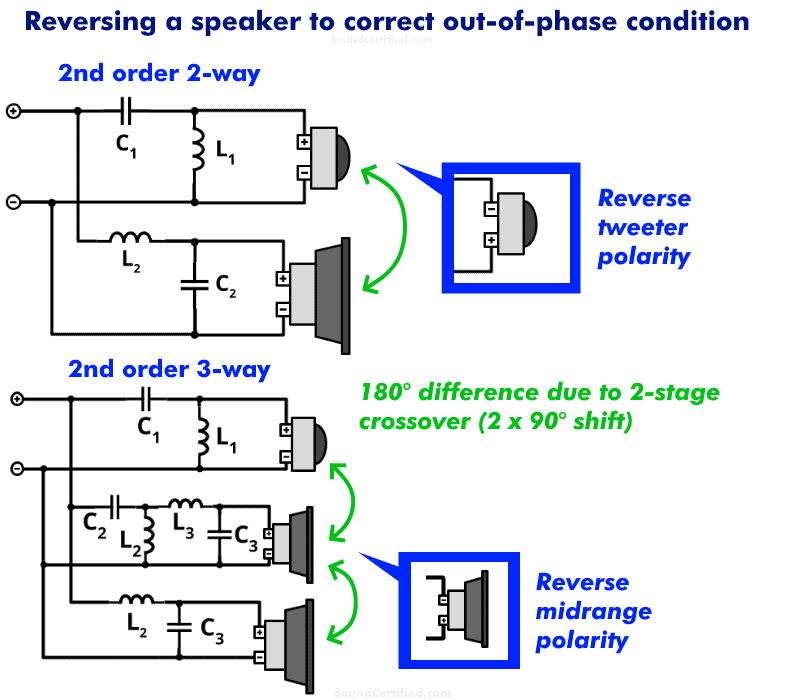

Second order networks have an output signal phase difference of 180 degrees. Fortunately, unlike odd-order designs (1st order or 3rd order), we can get an in-phase (0° difference) sound output easily.

To do this with second order networks:

- 2-way speaker systems: reverse the tweeter output crossover connections at the wire terminals and connect the tweeter like you normally would. This puts the tweeter back in phase with the woofer / bass driver.

- 3-way speaker systems: reverse the midrange polarity to the wire terminals for the crossover.

[Optional] Adding speaker wiring labels

Want to add an extra touch? You can easily make your own labels for your speaker and amplifier input connections. Personally, I recommend the following steps:

- Using copier or printer paper, write your connection label notes using a Sharpie permanent marker. Optionally you can print using a black and white printer (although it’s harder to get text lined up perfectly).

- Cut out the labels using scissors.

- Using clear tape such as large shipping tape, place the tape over the label and trim with scissors if needed.

- Apply the label to the project box.

Example of a finished DIY speaker crossover

Here’s an example of my own – one of my first DIY crossovers projects I built myself. As you can see it doesn’t have to be perfect – but does need to be well-connected, use the right parts, and be put together in a way that’s practical for everyday use.

Note that if you’re installing yours directly in a speaker enclosure it’s not necessary to use a project box, but the rest of the steps should still apply.

Hopefully you’ve found my guide helpful. Here’s to enjoying good sound the way you like it – and proving you can do it yourself!

Marty, I am a bit miffed when you state to “reverse” polarity of the components. Are you meaning connect the woofer terminals/wires (+ to +), (- to -) and then connect the tweeter terminals (+ to -), (- to +)? Why is this necessary? I usually connect + to + on both components and my projects sound just fine. Please elaborate.

Hello Ken.

Well, I’m referring to reversing the speaker wire connections to one wire terminal itself while building the crossover, but no components otherwise.

This is necessary for 2nd order crossovers because the tweeter and woofer (on 2-way systems) and the midrange (on 3-way) will be 180° out of phase with the other speaker(s).

You can often hear the difference when comparing them to in-phase speakers. Also, around the cutoff frequency, where the frequency range output of the tweeter and woofer overlap, there will be cancellation which will hurt performance.

The cancellation happens because one speaker will be moving exactly the opposite of the other speaker and soem sound waves will cancel each other out. If they’re far enough apart, however, you might not hear it.

The same principle applies when we put two subwoofers in a box and wire one it reverse – the sound will be noticeably lacking because of cancellation. Crossover manufacturers typically already reverse one speaker’s wire terminals internally so you don’t have to think about the crossover polarity.

Here’s a quote from The Loudspeaker Design Cookbook: “[..] second-order filters are 180° out of phase, but when the polarity is reversed, the phase is coincident.”

Best regards!